Protected at work

Workers who are exposed to hazardous chemicals or biological substances on an almost daily basis during the course of their work require first-class protection that is specially designed to cope with the conditions and potentially hazardous substances the wearer may be exposed to. The type of hazardous substance, as well as the degree and duration of exposure, are the key factors that determine which protective clothing is required. However, the proper use of the different types of disposable coveralls and the technology behind them – particularly the methods used to put on and remove the garments – is also of critical importance. Read on to find out all you need to know about disposable coveralls.

Types of uvex disposable coveralls

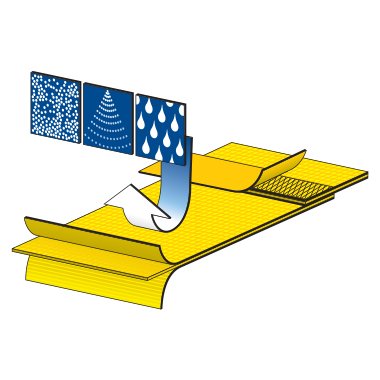

Type 3

- Liquid-tight protective coveralls

- EN 14605

- Certified according to Jet test

- PP spunbound laminated with PE film

Type 4

- Spray-tight protective coveralls

- EN 14605

- Certified according to Spray Test

- PP spunbound laminated with PE film

Type 5

- Particle-tight protective coveralls

- Protection against solid particles

- ISO 13982-1

- PP spunbound laminated with PE film

Type 6

- Limited spray tight protective coveralls

- Protection against liquid mist

- EN 13034

- PP SMMS material

Technology

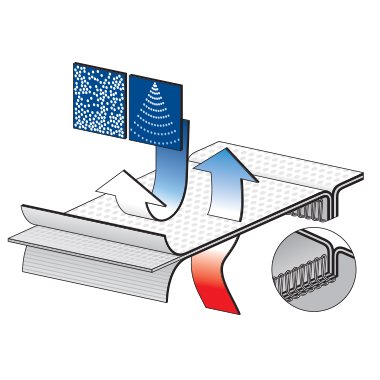

uvex sms

- Built out of several layers of polypropylene non-woven material

- Mixture of spunbond and melt-blown non-woven material for a perfect balance between stability and softness

- High degree of air permeability and breathability

uvex com4 laminate

- Non-woven polypropylene material laminated with a microporous polyethylene film

- Non-woven material on the inside for a comfortable feeling

- Material is not sticking on skin

- The microporous film provides a certain level on breathability

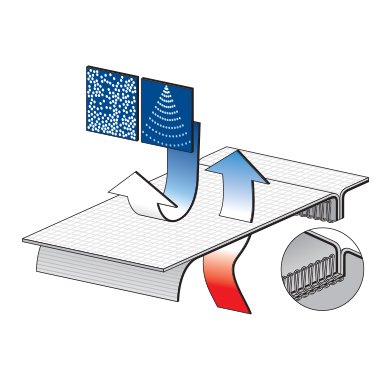

uvex laminate light

- Non-woven polypropylene material laminated with a polyethylene film

- Non-woven material on the inside for a comfortable feeling

- Material is not sticking on skin

- Using the film is providing a higher level of protection, but reduces the breathability

uvex laminate classic

- Non-woven polypropylene material laminated with a polypropylene film

- Non-woven material on the inside for a comfortable feeling

- Material is not sticking on skin

- The polypropylene film provides an effective barrier against many organic and inorganic liquid chemicals

Features and Benefits

1. 3 pieced hood

- Optimum fit

- No limitations of view

- Perfect match with respirators and goggles

- Soft elastic on edge, feels comfortable

2. Zipper flap

- Zipper flap with integrated self-adhesive tape

- Easy to gum up

- Additional security

3. Fingerloop

- Finger loops made of soft elastic

- To keep the sleeves at the wrist

- Additional security

4. Elasticated waistband

- Integrated elastic in the waist for optimal fit

- Ideal wearer comfort

5. Elasticated bands on arms and legs

- Convenient closures thanks to elastics at wrist and ankles for additional security

- Soft elastic on edge for high wearer comfort

uvex disposable coveralls at a glance

To ensure that your disposable coveralls deliver their full protective effect, it is important to put them on and take them off correctly. Certain steps must be performed in a defined order, and others may require the help of an assistant. We explain the steps to follow below.

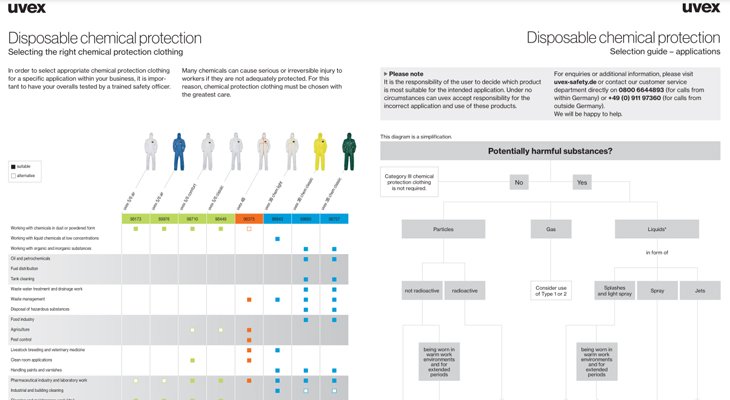

In order to select appropriate chemical protection clothing for a specific application within your business, it is important to have your coveralls tested by a trained safety officer. Many chemicals can cause serious or irreversible injury to workers if they are not adequately protected. For this reason, chemical protection clothing must be chosen with the greatest care.

Please note: It is the responsibility of the user to decide which product is most suitable for the intended application. Under no circumstances can uvex accept responsibility for the incorrect application and use of these products.

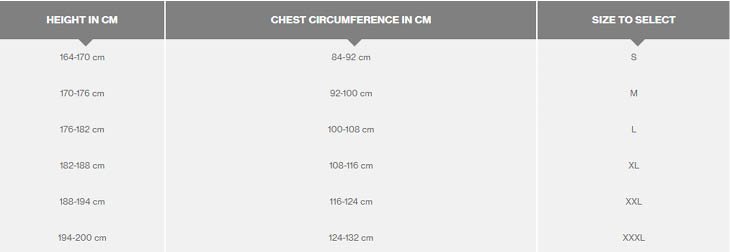

To ensure an optimum fit and keep the wearer safe when working with hazardous substances, uvex disposable coveralls are available in multiple sizes. However, the correct size may not be the same as your usual clothing size. Use the following overview to find the correct size based on your height and chest circumference.

Storage

uvex disposable protective clothing must be stored in its original packaging, protected from light and in a dry environment, at a temperature of between 15°C and 25°C.

Washing disposable coveralls

Disposable coveralls are intended as single-use garments and must not be washed.

Disposal

After use, the garments must be disposed of in accordance with the applicable legal regulations.

Storage life

We recommend that the product is used within five years of the production date indicated on the label.

The technical data sheets contain detailed information on the intended applications of the products, precise descriptions of the material properties and comprehensive product descriptions.

What are disposable coveralls used for?

Disposable coveralls are utilised to provide protection to the wearer against harmful particles, sprays and liquids. They are easy to put on and take off providing effective coverage to the entire body.

Who uses disposable coveralls?

Disposable coveralls are used in a variety of industries including mining, construction, food, and pharmaceutical, as well as any industries that expose workers to harmful chemicals, sprays, and gasses.

Why the type 5/6 coverall?

Are you exposed to dusty, damp, or wet conditions during your work?

Then an extremely lightweight, breathable type 5/6 disposable suit will provide you with an excellent combination of comfort and safety.

A certified particle-tight, limited spray-tight protective coverall for your day-to-day work applications.

Protective Coveralls: Your Ultimate Shield in Hazardous Work Environments

Individuals working in hazardous environments need protective clothing to safeguard them from potential harm. Among the most important of these PPE (protective personal equipment) are protective coveralls.